Scheme of IR Dryer for Glass Screen Printing Machine

TM-IR-G1501600

Infrared furnace circuit diagram

Infrared tunnel furnace cooling system

1. TM-IR-G1501600 Glass IR Dryer

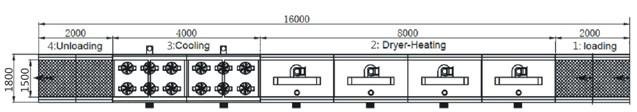

The glass dryer is used for drying and cooling the glass after screen printing. Machine 16m composed with 2m loading part + 4*2m drying part + 2*2m cooling part + 2m unloading part. Temperature adjustment range: room temperature -180 ° C

2. Features:

- Adopt standard material for the machine body, and stainless steel for the inner reflector.

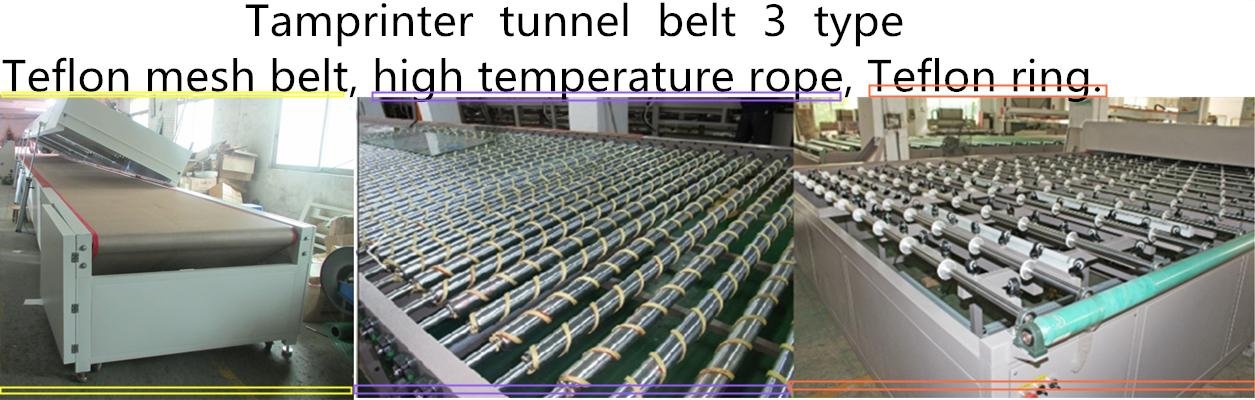

- Adopt imported gear motor for transportation. The glass is transported by the Teflon belt. If the budget is enough, please choose type 2 or 3

And the transportation speed is adjustable .

- There are high quality plastic rubber ring which with solvent resistance and high temperature resistance features.

- Adopt hot air convective circulation system.

- There are three sections of the dryer:

- First section: loading section.

- Second section: Drying section. There are 4 hot air drying sections. Adopt the high temperature motor to recycle the hot air from IR lamp. Make sure balanced heating on the glass. The temperature will be showed on the display. All 4 sections temperature can be controlled separately. There are two exhaust opening on the two sides of the heating section

- Third Section: Cooling section. Adopt motors to below the airs to both sides of the glass to realize the cooling function. The temperature can be cooled under 700C. Inside cooling sections, there are air filter system, and exhaust system, ensure balance between the air and exhausted air.

- Fourth Section: unloading section. Used to unload the glass after cooling. If the budget is enough, please choose: This section with up/down rack, on the racks, there are all-directions wheels and side roller to unload the glass. The foot switch is used to control the rack moving up and down.

- Cylinders used to lift up the cover of the dryer. It’s easy for after service and maintenance.

- Adopt high quality ceramic fiber insulation board for heating insulation. Increase heating efficiency.

- 8. We also can supply an over cross bridge for the dryer.

3. Technical Parameters

|

Width of dryer tunnel

|

1800mm

|

|

Feeding width

|

1500mm

|

|

Length of drying tunnel

|

16000mm

|

|

Feeding speed

|

2-6m/min

|

|

Adjusting range of temperature

|

Room temperature to 180℃

|

|

Power of infrared radiation tube

|

72. KW (1.5KW X 12pcsX 4 Sections)

|

|

Motor power

|

1.5KW

|

|

Total power

|

80KW, 380V, 50HZ

|

|

Air consumption

|

10L/Min, 6kg/c㎡

|

|

Mechanical dimension

|

16000×1800× 1600mm

|

|

Working Height

|

780~820mm adjustable

|

dryer glass screen printing sample

4. Main parts and brand:

1. Temperature Controller: Taiwan

3. Pneumatic parts: Taiwan Airtac

4. Converter: Taiwan Shilin

5. Driving motor: Taiwan Wanxing

6. Thermal protector: France Schneider

7. Reducer:Taiwan Liming

8. Mid Relay: Panasonic

9: Phase sequence protector:France Schneider

10:Three position switch: France Schneider

11: Solenoid valve: France Schneider

12: Temperature controller: Taiwan Yangming

Infrared Convection Oven ( shortwave )

1 imported shortwave infrared light radiation heating tube furnace used in all mirror panel system , equipped with special light tube reflector , can be 100% of all light reflection to the surface.

(2) using a uniform hair dedicated exclusively internal circulation duct temperature is very uniform.

3 equipped with imported light pipe dedicated controller, the frequency of light waves even control, the light pipe 100% to play full-wave energy, using current stable of 100% energy saving effect.

4 stainless steel chain and belt driven , easy to go astray , to load heavy metal category of products, with a special adjustment of the speed and stability.

5 light wavelength 0.76-1.6um, the strongest penetration , suitable transformer plant , electrical plant and other metal coil dipping baked or roasted dispensing electronic products .

Infrared Convection Oven ( MW )

1 medium-wave infrared light tubes imported radiant heating furnace used in all mirror panel production, with special reflector tube light , can be 100% of all light reflection to the surface.

(2) using a uniform temperature of the inner loop hair exclusive special duct temperature is very uniform.

3 equipped with imported light pipe dedicated controller, the frequency of light waves even control, the light pipe 100% to play full-wave energy, using current stable of 100% energy saving effect.

4 imported Teflon Wimbledon with a high resistance to rotation , suitable for the size class range of products , with a power converter, speed and stability .

5 light wavelength 0.76-3.6um, the surface absorbed the best baked products , such as glass, printing, textile printing , spray drying surface coating industry .

Infrared Convection Oven

Drying principles outlined

Conventional oven heating pipe heating using heat from the heated surface of the object to its internal thermal conductivity , so the heating process is slow, uneven heating , and some products first love hot conjunctival surface cause internal moisture can not get out , easy to produce bubbles or deformation.

Infrared Convection Oven is the use of energy efficient infrared light tubes imported produce infrared electromagnetic radiation directly to the object , so that objects within the molecular oscillation , internal and external heat simultaneously , quickly and thoroughly remove the moisture inside the object , the surface will not get out of the water inside the first dry produce surface blistering, internal roasted quit and so on.

Energy efficient advantages:

1 Energy: Infrared Convection Oven power than ordinary furnace small 1 / 3 , warming fast start ( 2-10 points can be raised to 200 degrees ) , the thermostat automatically reduces small current wave ( energy savings of 30% -70 % )

(2) Efficient : Infrared Convection Oven direct radiation makes the product molecular oscillation product , so the product simultaneously inside and outside heat, fast drying product moisture , direct -saving 5-10 times .

(3) quality and stability : infrared light to heat pipe heat inside and outside at the same time , the internal water discharged in time , the product surface is not easy to blister, uniform color appearance .

4 Green Explosion : Infrared Convection Oven baking time is short, short residence time before curing , the time to reduce pollution and harmful gases discharged in time , not stuffy harmful in the furnace , the furnace safe and clean , easy to produce flammable gas deflagration and other risks

hot tags: Electric IR Curing Machine