Tunnel furnace features:

●Heat control dry room temperature, room temperature -250C can be set arbitrarily with digital control.

●Equipped with a hot air circulation system, the temperature and air volume are uniform, so that the printed workpiece can be dried quickly, and the shrinkage rate is small, so as to ensure the overprinting accuracy of the printed piece.

●Mesh belt is driven by variable frequency motor with stepless speed regulation and digital display.

●The combination of multiple temperature zones in the furnace body can control the temperature independently.

Far-infrared tunnel furnace (basic parameters) special size can be customized

Conveying speed 1-1 0 mm/mim

Heating power 65kw

Temperature control value Normal temperature -250 C

Applicable power supply 380v

Temperature zone 8X2000mm

Total power 70kw

Uses: Applicable for glass, metal plates, ceramics and other high temperature resistant materials after silk screen printing and drying.

TY-

TY-

The tunnel furnace has excellent workmanship, scientific and reasonable structure, far-infrared heating method, uniform heating, high efficiency of electrothermal conversion, less noise, and convenient operation.

Center console: control each heating zone independently in groups, digital display, real-time monitoring of air volume/temperature, clear at a glance, convenient and quick to operate.

The stepless speed regulation switch is precisely adjusted, the display and the ammeter all use famous brand high-quality components, with reliable quality and stable performance.

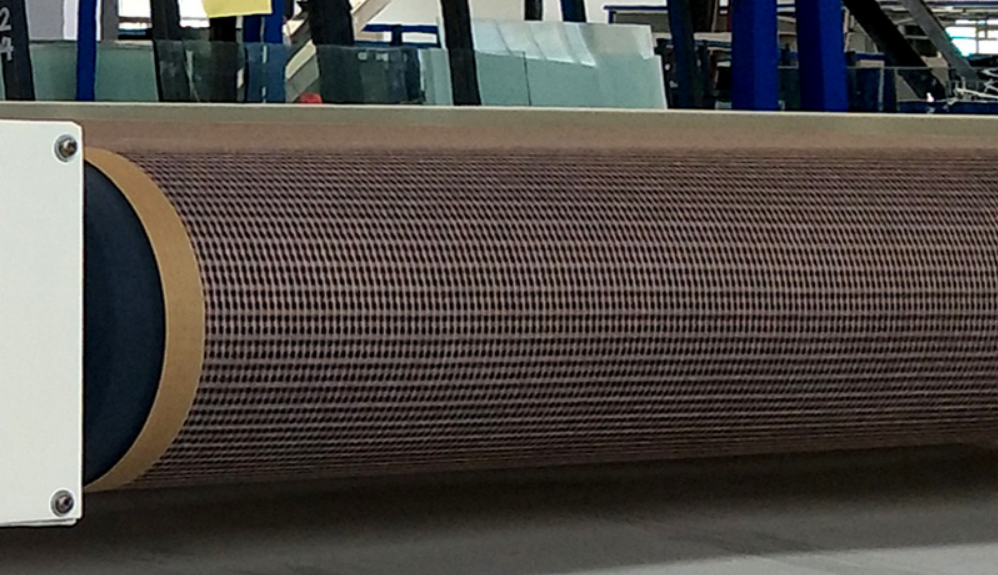

The tunnel furnace conveyor belt is made of Teflon material, which is resistant to high temperature and wear, and the shaft adopts a professional anti-skid device.

The tunnel furnace conveyor belt is equipped with 6 powerful fan devices at the end, which can cool down quickly and can be turned on/off independently to meet the cooling needs of different materials.

IR18130GL 13m roller coating Glass Infrared Tunnel Oven:

https://www.linkedin.com/feed/update/urn:li:activity:6390533810114699264

| L*W*H |

15.15*1.75*1.24M |

| sus Belt to earth |

0.75M |

| Total wattage |

70KW |

| Wind fan wattage |

150W/220V*20 |

| Conveyer motor wattage |

90W/1P/220V |

| ConveyEr speed |

0~25m/min |

| Speed adjustment |

Stepless |

| Heater Lamp wattage |

1.5Kw/220V×45pcs |

| Max height of production |

100mm |

| Weight |

2400kg |

| Conveyer width |

1500mm |

| Entering length |

1m |

| Heat area |

10m |

| Cool area Length |

3m |

| Exit length |

1m |

| Total Length |

15m |

15m glass infrared tunnel dryer Technology

Tamprinter Infrared Convection Oven ( shortwave )

1 imported shortwave infrared light radiation heating tube furnace used in all mirror panel system , equipped with special light tube reflector , can be 100% of all light reflection to the surface.

(2) using a uniform hair dedicated exclusively internal circulation duct temperature is very uniform.

3 equipped with imported light pipe dedicated controller, the frequency of light waves even control, the light pipe 100% to play full-wave energy, using current stable of 100% energy saving effect.

4 stainless steel chain and belt driven , easy to go astray , to load heavy metal category of products, with a special adjustment of the speed and stability.

5 light wavelength 0.76-1.6um, the strongest penetration , suitable transformer plant , electrical plant and other metal coil dipping baked or roasted dispensing electronic products .

Tamprinter Infrared Convection dryer ( MW )

1 medium-wave infrared light tubes imported radiant heating furnace used in all mirror panel production, with special reflector tube light , can be 100% of all light reflection to the surface.

(2) using a uniform temperature of the inner loop hair exclusive special duct temperature is very uniform.

3 equipped with imported light pipe dedicated controller, the frequency of light waves even control, the light pipe 100% to play full-wave energy, using current stable of 100% energy saving effect.

4 imported Teflon Wimbledon with a high resistance to rotation , suitable for the size class range of products , with a power converter, speed and stability .

5 light wavelength 0.76-3.6um, the surface absorbed the best baked products , such as glass, printing, textile printing , spray drying surface coating industry .

Tamprinter Infrared Convection tunnel

Drying principles outlined

Conventional oven heating pipe heating using heat from the heated surface of the object to its internal thermal conductivity , so the heating process is slow, uneven heating , and some products first love hot conjunctival surface cause internal moisture can not get out , easy to produce bubbles or deformation.

Infrared Convection Oven is the use of energy efficient infrared light tubes imported produce infrared electromagnetic radiation directly to the object , so that objects within the molecular oscillation , internal and external heat simultaneously ,tam@tamprinter.com quickly and thoroughly remove the moisture inside the object , the surface will not get out of the water inside the first dry produce surface blistering, internal roasted quit and so on.

Energy efficient advantages:

1 Energy: Infrared Convection Oven power than ordinary furnace small 1 / 3 , warming fast start ( 2-10 points can be raised to 200 degrees ) , the thermostat automatically reduces small current wave ( energy savings of 30% -70 % )

(2) Efficient : Infrared Convection Oven direct radiation makes the product molecular oscillation product , so the product simultaneously inside and outside heat, fast drying product moisture , direct -saving 5-10 times .

(3) quality and stability : infrared light to heat pipe heat inside and outside at the same time , the internal water discharged in time , the product surface is not easy to blister, uniform color appearance .

4 Green Explosion : Infrared Convection Oven baking time is short, short residence time before curing , the time to reduce pollution and harmful gases discharged in time , not stuffy harmful in the furnace , the furnace safe and clean , easy to produce flammable gas deflagration and other risks

hot tags: Industrial IR Curing Machine