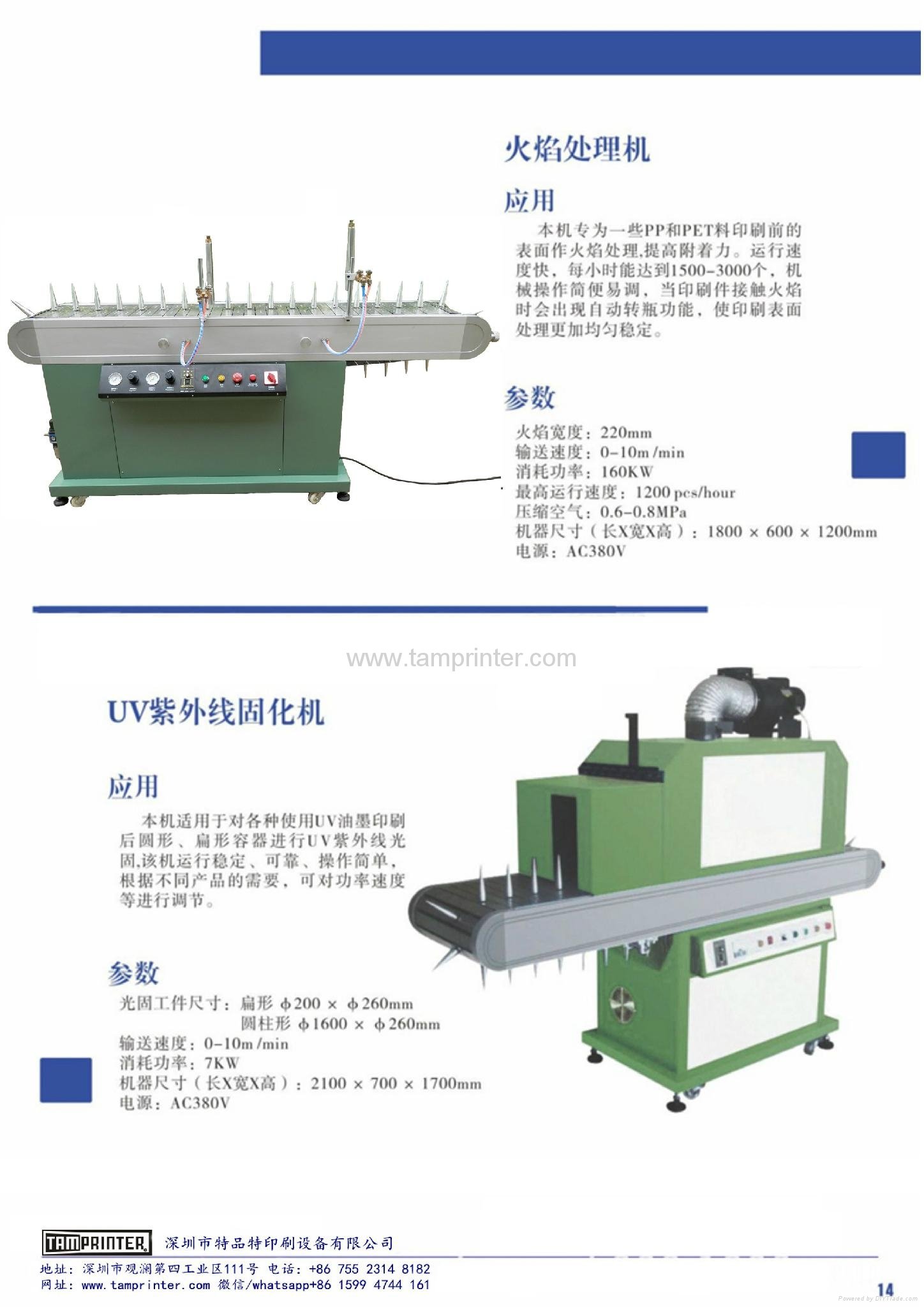

Air-Gas burner Bottle flame treatment machine with automatic ignition and product dwell and simultaneous rotation made in china tamprinter brand shenzhen factory

How to work video:

http://v.youku.com/v_show/id_XNTE1NDE2MDQw.html

8419899090 flame processor test video

https://youtube.com/shorts/5WvD1bNp9Eo?feature=share

bottle container the flame processor, Basketball board large flat flame processor, electric car shell Flame Treatment Machine, continuous PP tube Flame Treatment, car bumpers flame processor equipment.

|

Specifications:

| lame area |

25~250mm |

| Height of work piece |

25-250 mm |

| Bottle mouth diameter |

12-24mm |

| Conveyer size |

230mm |

| Output |

1800~3000Pcs/Hr |

| Conveyer transfer speed |

0-10m/min |

| Compress air |

6 bar |

| Fuels for flame processor |

liquefied petroleum gas |

| Power supply |

AC 220V/ 50Hz, 1-Phase |

| Machine dimension |

2200X1200X700 mm (LXWXH) |

| Machine weight |

155 KG |

|

|

Operational issues :

1 This machine uses 220V power supply, and combustible gases, and compressed by the compressor air ventilation when using the machine and away from danger highly flammable areas where conditions permit the best equipped with fire fighting equipment !

(2) The machine has a certain degree of risk, please pay attention to safety when using operator and the operator has certain associated processing consciousness !

Boot steps:

1 Plug 220V power supply, and pass on the combustible gas and compressed air , the air pressure is about 3-4KG around ! Followed by seeing, hearing, smell and other methods to check whether there is leakage of the place , check Do not use open flame check , to avoid danger , you can use soapy water to check for leaks ! Checked and then wipe to dry !

2 Open the emergency stop switch power to start the governor , confirmed a few weeks to let the whole operation and commissioning of the sharp turn running OK , and then press the combustible gas switch , and then try to turn on the combustible gas flame gun switch, ( just started not too wide ) then the ignition , allowing the flames to light , and then slowly open the air switch, and gas -switch synchronous adjustment , adjusted to the blue flames

On behalf of the flame has been adjusted , press workpiece speed and running speed , try to adjust the position of both sides of the flame , the flame come into contact with the surface, quickly through !

3 tables under a pressure regulator , a pressure regulator only on behalf of the combustible gas meter , and the other is an air pressure adjustment table , generally regulated at 3-4KG so on it !

4 Configure the emergency stop switch , under any circumstances , press the emergency stop switch, the machine will stop , but the machine is stopped, the combustible gas will shut down, but for safety reasons, turn off the gas main switch should be relatively synchronized properly !

5 When the work is shut down , turn off the combustible gas switch , first extinguish the flame , the flame gun surface is heat, please do not touch , so as not to burn , you can allow free air circulation for some time and then turn off the air ! In order to achieve the cooling effect ! From work and want to turn off the power switch, and combustible gas master switch for safety !

Packaging Detail: Plywood case

Delivery Detail: Within 7 days

The 2 spark flame treatment machine is use for pre-treatment PP,PET,

and PE bottle surface before printing.