Model No.︰-

Brand Name︰Tamprinter

Country of Origin︰China

Unit Price︰US $ 25000 / set

Minimum Order︰1 set

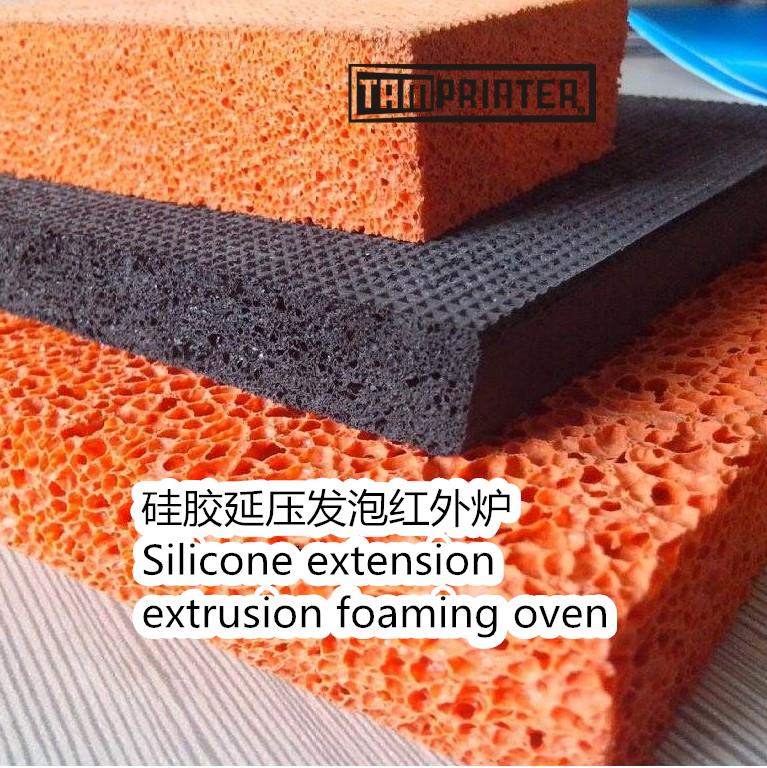

silicone sponge rubber manufacturing tunnel oven

480v 3phase 60hz

Independent power control cabinet

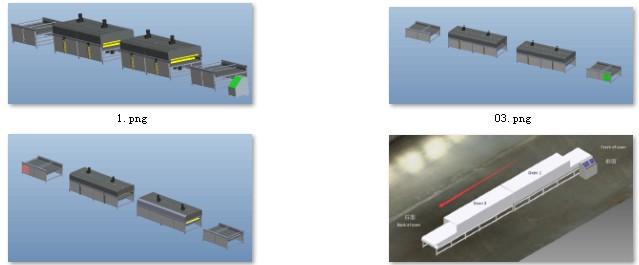

14 m * 1.4m * 1.3m

Inlet 2m Outlet 2m

4 zones ,2.5m per heat zones.

2+2.5+2.5+2.5+2.5+2=14

370W*2PCS motors control 2 belt

2 belt speed controllers adjust each 7 m (2 +2.5+2.5 m)

Teflon belt width: 1.2 m

Belt mesh hole 2 x 2mm

Vulcanization: 180~230 Celsius

far infrared Lamp heat to top and bottom

Top 15pcs

Bottom 15pcs

15*1kw+15*1kw= 30kw

(top and bottom heaters on separate controls)

Internal circulation fan 750W*4PCS

4 cylinder Lift open oven cover

2 'Exit'=Exhaust gas or smoke exhaust

Silicone calendering foaming oven

Thanks to outstanding calendering process capability, General Silicones (GS) are able to offer diverse silicone sheets and films that can be applied in automobiles, industrial electronics, consumer electronics, OA machines, medical markets, etc. GS can produce various silicone calendered sheet and film products according to the raw material properties, specifications, and surface texture (embossment) required by customers. In order to cope with the growth of the optoelectronics industry and the increasing demand for silicone pad and sheet products, our factory have automated production line for sheet calendering process. From raw material supply, product research and development to design, you will be fully satisfied at our one-stop production and service.

3d drawing for tunnel dryer

Why Silicone?

Benefits of using silicone rubber

1,TEMPERATURE

Silicone rubber is one of the few elastomers that has the ability to perform in extreme temperatures on both sides of the scale. The range of silicone sponge products will withstand temperatures of -76°F to +446°F for sustained periods in application, whilst the special grades formulated with the addition of heat stabilisers take the maximum working temperature of the silicone as high as +570°F.

2. WEATHERING

Silicone has incredible resistance to weathering and environmental influences. Over time, there is very little change to the properties of silicone when exposed to the elements. Silicone is also resistant to ozone, oxidation, ultraviolet light, corona discharge, cosmic radiation, ionising radiation and general weathering.

3. INERTNESS

Silicone rubber is a stable elastomer that will not cause staining, corrosion, or deterioration of other materials it has contact with and does not support fungal growth.

4. LOW COMPRESSION SET

Excellent compression set properties of sponge silicone makes it the elastomer of choice for sealing applications at adverse temperatures ranges.

5. VERSATILITY

Silicone extrusions are used in a wide range of everyday products and equipment and are usually used for sealing applications. Commonly used in industrial and commercial applications where there can be extensive temperature variations from light fittings and door seals in ovens to gaskets in HVAC and automotive, especially the new breed of electric vehicles being developed.

Payment Terms︰ tt

![]()