Model No.︰tm-z9

Brand Name︰Tamprinter

Country of Origin︰China

Unit Price︰US $ 1079 / set

Minimum Order︰1 set

TDY-300 High Speed Small Electric Pad Printer -----1set---x $380

+ portable uv curing machine------------------------------1set---x $315

+TM-H35 Printing steel plate special oven------------- 1set---x $290

+SC-280 BSF Mini Exposure Machine-------------------1set---x $100

+ Thin Steel Plates cliches----------------------------------10pcs x $10=$100

+ Silicone Pad -------------------------------------------------10pcs x $10=$100

+Exposure lamp ----------------------------------------------1pcs --x $10

+uv lamp--------------------------------------------------------1pcs --x $50

=$1079

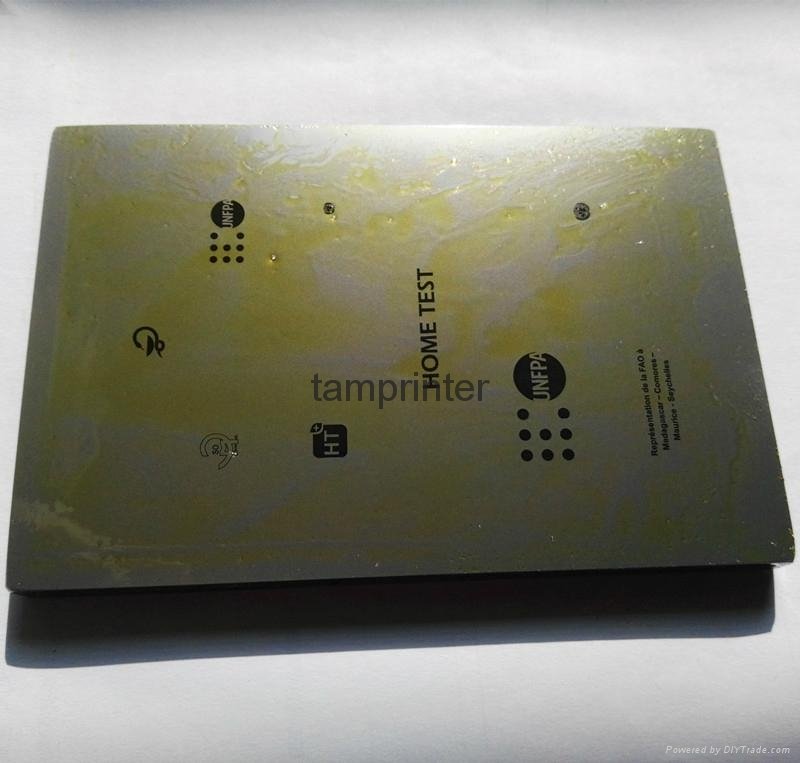

Pad printing is a printing process that can transfer a 2-D image onto a 3-D object. This is accomplished using an indirect offset (gravure) printing process that involves an image being transferred from the printing plate (cliché) via a silicone pad onto a substrate (surface to be printed). Pad printing is used for printing on otherwise impossible products in many industries including medical, automotive, promotional, apparel, electronics, appliances, sports equipment and toys. It can also be used to deposit functional materials such as conductive inks, adhesives, dyes and lubricants.

Physical changes within the ink film both on the cliché and on the pad allow it leave the etched image area in favor of adhering to the pad, and to subsequently release from the pad in favor of adhering to the substrate (material being printed).

The unique properties of the silicone pad enable it to pick the image up from a flat plane and transfer it to a variety of surface (i.e. flat, cylindrical, spherical, compound angles, textures, concave surfaces, convex surfaces).

Why use pad printing ?

Pad printing is used for printing on various substrates like Plastics, Metals, Glass and Ceramics, Paper and Cardboard, Leather. However, it is primary used in places where the printing area is small and / or the contour or surface of the object is not flat or hard to reach by other printing process.

* Engineering items

* Golf products

* Hangers

* Highlighters

* Key rings

* Letter openers

* Lighters* Mugs

* Paper weights

* Pens

* Pencils

* Rulers

* Sunglasses * Ashtrays

* Bicycle helmets

* Brochure holders

* Business card holders

* Calculators

* Cassettes

* Coasters

* Computer products

* Construction helmets

* Badges

* Telephone boards

* Toys

* Mobile phone holders

Pad printing work includes 2 processes: Plate making Process and Printing Process

hot tags: pad printer, pad printing machine, pad printer, pad printing machine, manual pad printer, manual pad printing machine, pad printers for sale

Payment Terms︰ TT/Western Union