Model No.︰TM-IR-G1501600

Brand Name︰Tamprinter

Country of Origin︰China

Unit Price︰US $ 16888 / set

Minimum Order︰1 set

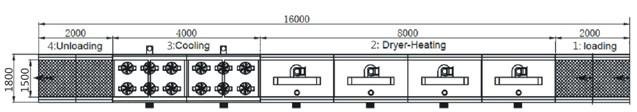

Scheme of IR Dryer for Glass Screen Printing Machine

TM-IR-G1501600

Infrared furnace circuit diagram

Infrared tunnel furnace cooling system

1. TM-IR-G1501600 Glass IR Dryer

The glass dryer is used for drying and cooling the glass after screen printing. Machine 16m composed with 2m loading part + 4*2m drying part + 2*2m cooling part + 2m unloading part. Temperature adjustment range: room temperature -180 ° C

2. Features:

And the transportation speed is adjustable .

3. Technical Parameters

|

Width of dryer tunnel |

1800mm |

|

Feeding width |

1500mm |

|

Length of drying tunnel |

16000mm |

|

Feeding speed |

2-6m/min |

|

Adjusting range of temperature |

Room temperature to 180℃ |

|

Power of infrared radiation tube |

72. KW (1.5KW X 12pcsX 4 Sections) |

|

Motor power |

1.5KW |

|

Total power |

80KW, 380V, 50HZ |

|

Air consumption |

10L/Min, 6kg/c㎡ |

|

Mechanical dimension |

16000×1800× 1600mm |

|

Working Height |

780~820mm adjustable |

dryer glass screen printing sample

4. Main parts and brand:

1. Temperature Controller: Taiwan

3. Pneumatic parts: Taiwan Airtac

4. Converter: Taiwan Shilin

5. Driving motor: Taiwan Wanxing

6. Thermal protector: France Schneider

7. Reducer:Taiwan Liming

8. Mid Relay: Panasonic

9: Phase sequence protector:France Schneider

10:Three position switch: France Schneider

11: Solenoid valve: France Schneider

12: Temperature controller: Taiwan Yangming

Infrared Convection Oven ( shortwave )

1 imported shortwave infrared light radiation heating tube furnace used in all mirror panel system , equipped with special light tube reflector , can be 100% of all light reflection to the surface.

(2) using a uniform hair dedicated exclusively internal circulation duct temperature is very uniform.

3 equipped with imported light pipe dedicated controller, the frequency of light waves even control, the light pipe 100% to play full-wave energy, using current stable of 100% energy saving effect.

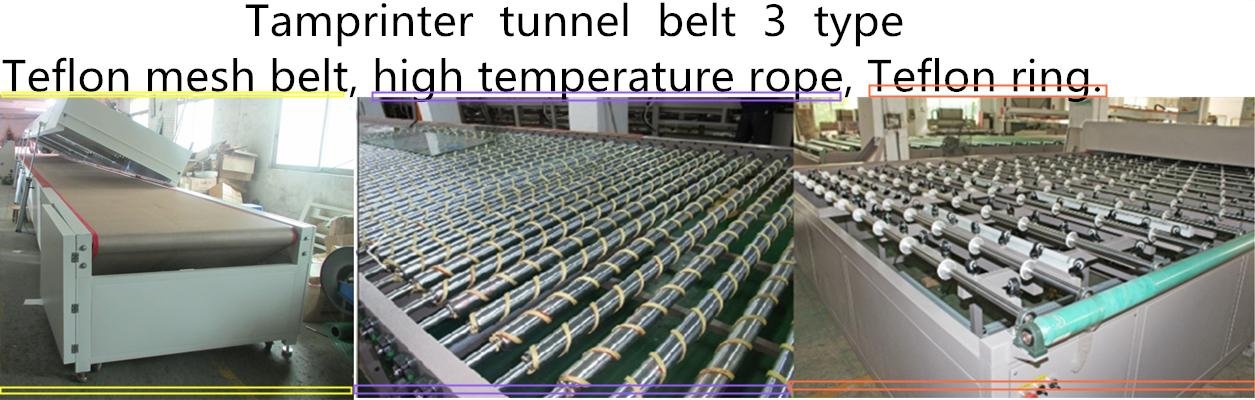

4 stainless steel chain and belt driven , easy to go astray , to load heavy metal category of products, with a special adjustment of the speed and stability.

5 light wavelength 0.76-1.6um, the strongest penetration , suitable transformer plant , electrical plant and other metal coil dipping baked or roasted dispensing electronic products .

Infrared Convection Oven ( MW )

1 medium-wave infrared light tubes imported radiant heating furnace used in all mirror panel production, with special reflector tube light , can be 100% of all light reflection to the surface.

(2) using a uniform temperature of the inner loop hair exclusive special duct temperature is very uniform.

3 equipped with imported light pipe dedicated controller, the frequency of light waves even control, the light pipe 100% to play full-wave energy, using current stable of 100% energy saving effect.

4 imported Teflon Wimbledon with a high resistance to rotation , suitable for the size class range of products , with a power converter, speed and stability .

5 light wavelength 0.76-3.6um, the surface absorbed the best baked products , such as glass, printing, textile printing , spray drying surface coating industry .

Infrared Convection Oven

Drying principles outlined

Conventional oven heating pipe heating using heat from the heated surface of the object to its internal thermal conductivity , so the heating process is slow, uneven heating , and some products first love hot conjunctival surface cause internal moisture can not get out , easy to produce bubbles or deformation.

Infrared Convection Oven is the use of energy efficient infrared light tubes imported produce infrared electromagnetic radiation directly to the object , so that objects within the molecular oscillation , internal and external heat simultaneously , quickly and thoroughly remove the moisture inside the object , the surface will not get out of the water inside the first dry produce surface blistering, internal roasted quit and so on.

Energy efficient advantages:

1 Energy: Infrared Convection Oven power than ordinary furnace small 1 / 3 , warming fast start ( 2-10 points can be raised to 200 degrees ) , the thermostat automatically reduces small current wave ( energy savings of 30% -70 % )

(2) Efficient : Infrared Convection Oven direct radiation makes the product molecular oscillation product , so the product simultaneously inside and outside heat, fast drying product moisture , direct -saving 5-10 times .

(3) quality and stability : infrared light to heat pipe heat inside and outside at the same time , the internal water discharged in time , the product surface is not easy to blister, uniform color appearance .

4 Green Explosion : Infrared Convection Oven baking time is short, short residence time before curing , the time to reduce pollution and harmful gases discharged in time , not stuffy harmful in the furnace , the furnace safe and clean , easy to produce flammable gas deflagration and other risks

hot tags: Electric IR Curing Machine

Payment Terms︰ TT/LC/western union