Model No.︰TM-AG900

Brand Name︰Tamprinter

Country of Origin︰China

Unit Price︰US $ 6688 / set

Minimum Order︰1 set

Tamprinter glitter powder machine The operating principle video

https://youtu.be/IyzDyWEjl5g

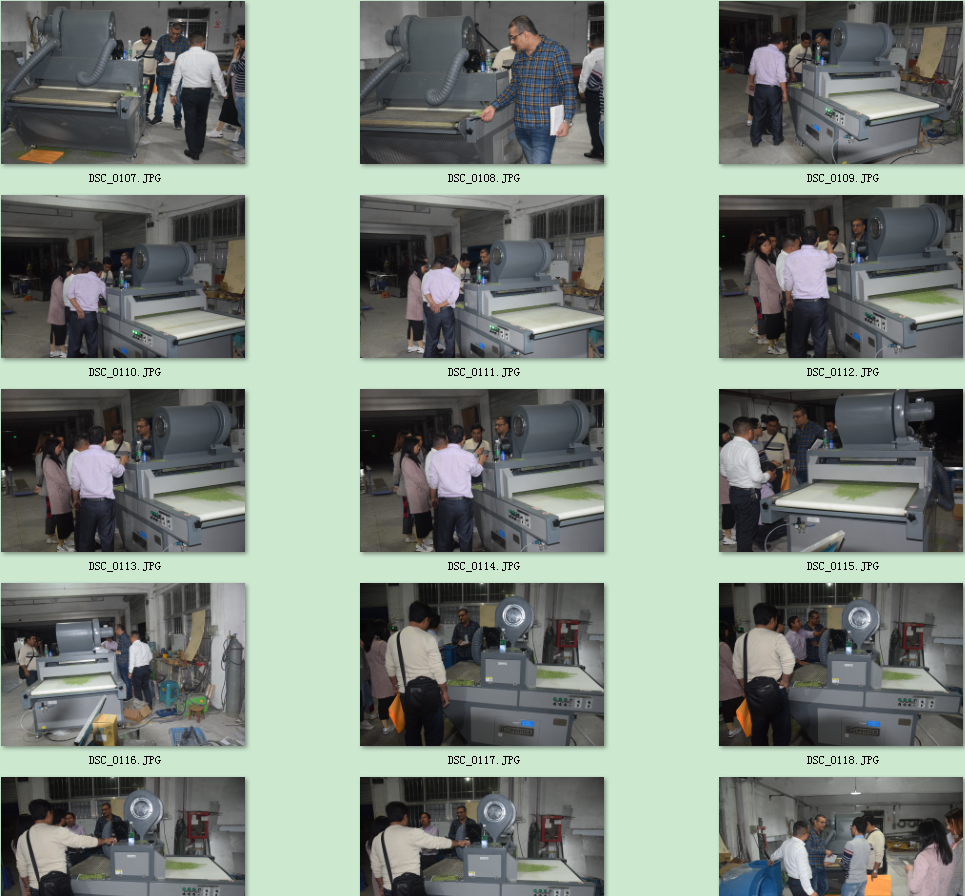

1. Technical parameter:

| Commodity name | Automatic gold powder machine | glittle powder machine |

| Power | 380V-3phase/2KW | 380V-3phase/2.5KW |

| Conveyor belt width (mm) | 920mm | 1120mm |

| Paper thickness | more than 80g | more than 80g |

| Dimensions | 2300X1420X2100mm | 2200X1500X2000mm |

| Weight | 290kg | 350kg |

| Dusting width | 900mm | 1100mm |

The process flow is the same. Glitter powder can be sprinkled on paper or leather, or on fabric, in the same way.

Step 1: Apply glue to substrates such as paper, and apply glue or pattern silk-screen glue to the surface of the product to be dusted, usually white glue or UV glue

Step 2: The glue has not dried yet, start dusting, and pressurize it if necessary.

Step 3: Enter the cleaning box, absorb or brush off the excess gold powder, if it is a pattern of glue silk screen printing, no glue outside the pattern area will not absorb the glitter powder and be sucked away.

Step 4: Coat or screen-print the powdered surface with glue (transparent treatment type glue) (optional)

The fifth step: drying by ultraviolet or infrared drying tunnel

Step 6: Gold glitter finished products are stacked or rolled.

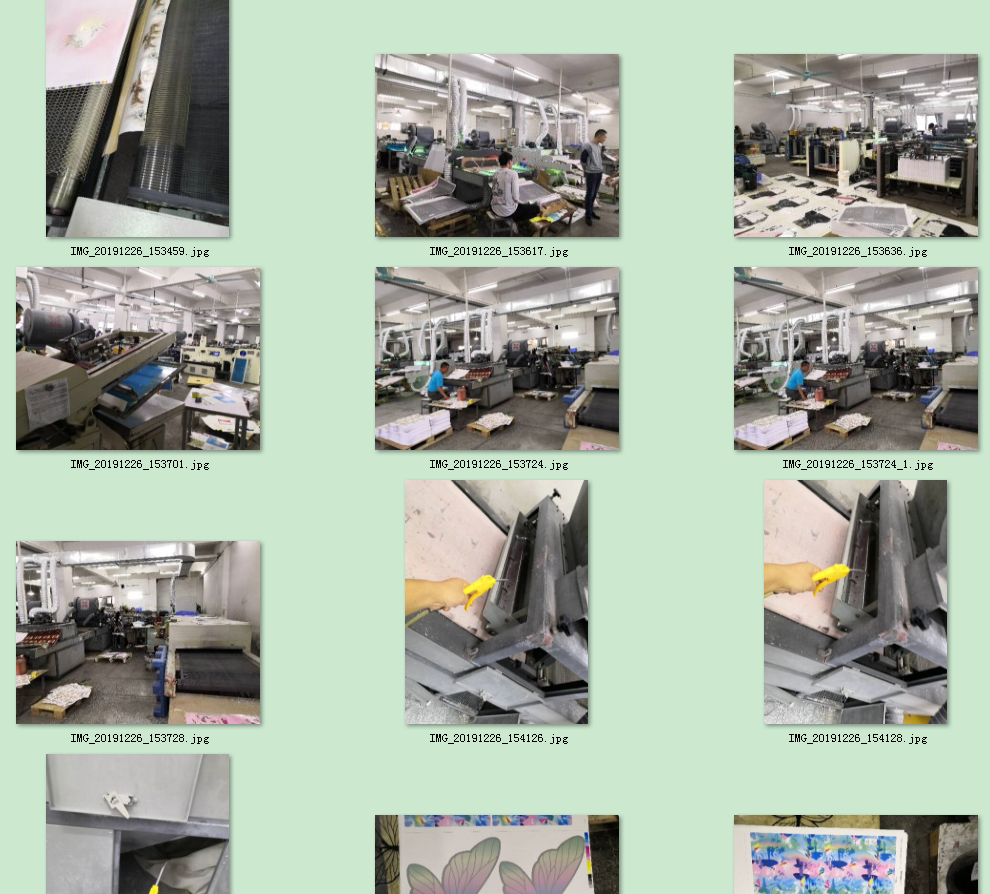

2. Application:

It is apply to the color powder spraying of the greeting cards, textile, vanities, leather, etc.

3. Feature:

An after-printing machine instead of traditional hand glitter powder printing; easy use; non-dusting; used with screen printing machine can increase efficiency greatly, increase the use rate of glitter powder; make various pictures with glitter powder.

If necessary, connect to UV light curing unit and infrared-ray dryer, etc.

Key components, such as conveyer belt, blower, transducer are imported from advanced technology country, so that the machine will be more steady and durable.

Stick gold powder, Use white glue will be cheaper than the uv glue, but be sucked particles clog the suction inlet, need to often clean the suction inlet

Tamprinter glitter powder machine has an alias:

Glitter powder dusting machine, Glitter powder coating machine, Glitter powder laminating machine.

Patent name: production method of automatic glitter powder machine

Technical field:

The utility model relates to the processing field of the post-printing process of paper, which is an automatic glitter powder machine.

2. Technical background

At present, the process of spraying glitter powder on printing paper is mostly done manually, that is, manually sprinkle the glitter powder on the paper with the printed pattern evenly. The glitter powder is shaken off manually or blown away by compressed air, because the glitter powder itself is small in size and light in weight, which can easily cause dust pollution in the workshop, which has a great impact on the health of the operators themselves and the surrounding environment. , and the glitter powder cannot be recycled more thoroughly.

Although the utility model patent of automatic glitter powder machine improves the degree of automation, reduces labor, and can also recover some excess glitter powder to a certain extent, there are defects such as only a single suction port and a single suction port in structure. The conveyor belt device is equipped with a pinch roller on the conveyor belt, which causes scratches on the surface of the printed matter and more glitter powder on the back of the printed matter. The finer powder is easier to stick, and it still needs to be done manually or by a compressor. Removal, resulting in increased labor and environmental pollution, especially high-end printed matter must not allow the printed matter to be scratched and the phenomenon of sticking powder on the back.

3. Content of the Invention

Aiming at the defects existing in the decoration of the above-mentioned printed matter such as paper, the utility model provides a fully automatic glitter powder machine that can achieve that the printed matter is not scratched and can fully recycle the excess glitter powder in the subsequent process.

The technical scheme of the fully automatic glitter powder machine is that it includes a dusting device, a recovery device, a conveying device and an upper and lower frame, and is characterized in that the dusting device and part of the recovery device are arranged in the upper frame, and A wind powder The separator and B air powder separator are arranged side by side on the upper frame, the upper frame is arranged on the lower frame, the conveying device is arranged under the dusting device, and the upper suction port is arranged on the upper frame.

The suction pipe is connected with the A-wind powder separator, and the left side of the upper suction pipe is connected with the powder collecting hopper powder recovery pipe, so that the powder collecting hopper can be recovered into the dusting hopper; B is connected to the air powder separator. The lower part of the lower suction pipe is connected to the lower suction port equipped with a rotatable paper roller. The upper suction port is opposite to the lower suction port to form a double suction port device. The printed matter passes between the upper and lower suction ports. Suck it up, the paper roller supports the printed matter without being scratched, and the excess powder on the top and back of the printed matter can be recycled into the powder hopper for reuse, so as to save the glitter powder. The dusting device is composed of a dusting hopper, a dusting switch and a spring sheet. The dusting switch is connected with the dusting port of the dusting hopper. The dusting hopper is fixed in the upper frame through the spring sheet. The dusting hopper is set. Below the lower powder port; in the recovery device, two air powder separators A and B with fans are fixed side by side above the upper frame, the right outlet is connected to the lower powder port, and the left port of the A air powder separator is connected to the upper The suction pipe is connected, the upper suction pipe is connected with the upper suction port, the left side of the upper suction pipe is connected with the upper part of the powder collecting hopper powder recovery pipe, and the lower part is openly connected with the lower part of the powder collecting hopper; The upper part of the pipe is connected to the lower suction port, and the lower part is connected to the lower suction port to form a double suction port device. One of the upper and lower suction ports is on the top and the other is on the bottom. In the described conveying device, the conveying belt is divided into two sections, and several beef tendons are embedded in the semi-circular arc groove of the transmission shaft to fix the conveying belt from deviation. In the double suction port double conveyor belt device, a lower suction port is set in the middle of the two sections of the conveyor belt, and there are several rotatable paper rollers inside, which are located between the lower frame and the upper frame, thus forming a double suction port and double conveying. Belt device, the advantage of adopting the invention is that the printed matter is automatically sprinkled with glitter powder, which has a high degree of automation and reduces labor intensity; The lower suction port is supported by the paper support roller, which will not scratch the printed matter; after the printed matter is printed, the excess glitter powder on the top and back of the printed matter and the powder in the powder collecting hopper can all be recovered into the powder hopper for recycling, not only Reduce environmental pollution, and improve productivity and print quality.

Four

Fig. 1 is the front view structure of the fully automatic glitter powder machine of the present invention.

Figure 2 is a left side view of the fully automatic glitter powder machine of the present invention.

1. Conveying motor; 2. Powder collecting hopper; 3. Lower suction port; 4. Lower frame; 5. Outlet conveyor belt drive shaft; 6. Outlet conveyor belt; 7. Short pad; 8. Upper suction port; 9 , upper frame; 10, adjusting screw; 11, lower powder port; 12, spring sheet; 13, dusting bucket; 14, dusting switch; 15, inlet conveyor belt drive shaft; 16, inlet conveyor belt; 17, long Backing plate; 18. Brush roller; 19. Electrical control panel; 20. Powder collecting hopper powder recovery pipe; 21. Lower suction pipe; 22. Upper suction pipe; 23. Fan seat; 24. Fan A; 25. Fan A Powder separator; 26, B air powder separator; 27, B fan; 28, electric box.

Five specific implementations

The specific implementation of the present utility model will be further described below with reference to the accompanying drawings. (1) During the installation process, the lower frame is placed in a horizontal position. The powder collecting hopper 2 and the lower frame 4 are welded together, and part of the lower suction port is installed in the lower frame 4. Pipe 21, connect the lower suction port with the lower suction pipe 21, install the brush roller 18 in the lower frame 4, and then put the two outlet conveyor belt shafts 5 in the outlet conveyor belt 6 at the outlet, and put on the bearing, It is fixed in the lower frame 4, and the short backing plate 7 is also placed in the outlet conveyor belt and rests on the two support rods. Install the inlet conveyor belt 16 on the right side of the lower suction port 3 , set the inlet conveyor belt drive shaft 15 in the inlet conveyor belt 16 , install the bearing and bearing shell, and insert each beef tendon strip into the semicircular arc groove of the drive shaft 15 In the middle, the bearing shell of the rear axle after tightening the tendon is fastened in the lower frame 4, and then the long backing plate 17 is set in the inlet conveyor belt 16, so that the hollow part of the long backing plate 17 is placed under the dusting hopper, so that the The powder that is not sprinkled on the printed matter falls into the powder collecting hopper 2, and a cardboard stopper with as many open long grooves as the number of beef tendon strips is arranged on the long backing plate 17, and each strip is inserted into the open long grooves. Then push the stopper to the top of the inlet conveyor belt drive shaft, touch the upper suction port, and use a screw to

Long backing plates 17 are fastened together. The upper frame is arranged on the lower frame 4, and then the A and B air powder separators (25, 26) are placed side by side, connected with the upper frame 9, and the lower powder port 11 is simultaneously connected with the A and B air powder separators. In the outlet connection, the left interface of the A-wind powder separator 25 is connected with the upper suction pipe 22, the lower part of the upper suction pipe 22 is connected with the upper suction port, and the left side is connected with the open opening of the powder collecting hopper through the powder collecting hopper powder recovery pipe to form a powder collecting hopper. The powder recovery channel in the hopper, and the excess powder on the printed product is recovered through the upper suction port 8 and the upper suction port pipeline 22, and the two share the A wind powder separator 25 to complete the powder recovery, and send it to the powder hopper through the lower powder port 11. B. The left port of the air powder separator 26 is connected to the upper part of the lower suction pipe 21, and the lower part is connected to the lower suction port in the lower frame 4 to form a second powder recovery channel. At the same time, it can also absorb the excess powder on the printed matter, as well as the powder on the back of the printed matter, and install the transmission parts, conveying motor, powder outlet motor, dusting motor, etc.

(2) Turn on the power supply during use, fill the powder hopper with glitter powder, turn on the power switch, and turn on the two air powder separator motors, conveyor belt motor, powder sprinkler motor, and powder outlet motor in turn, and adjust and adjust The screw can make the printed matter pass between the upper and lower suction ports. Adjust the frequency of the A fan to 45 and the frequency of the B fan to 65, so that the A wind powder separator will not suck the printed matter, and the excess powder on the printed matter will be collected. The powder in the bucket can be continuously recycled to the dusting bucket. The B air powder separator can absorb the printed matter, and can recover the excess powder on the printed matter and the powder adhered to the back of the printed matter to the dusting hopper. Put the printed matter on the conveyor belt at the entrance, the printed matter will move from right to left, and sprinkle with glitter powder under the dusting hopper. The glitter powder will fall into the powder collecting hopper at the place where there is no printed matter, and the printed matter will continue to move to the left. During the time between the upper and lower suction mouths, the printed product is sucked by the lower suction mouth, the excess powder on the printed product is sucked by the upper and lower suction mouths, and the powder stuck on the back is sucked by the lower suction mouth. The printed product continues to move to the left, and continues to move the printed product out of the machine when moving to the exit conveyor belt. Finished the process of spraying glitter powder on the printed matter, ensuring the quality of the printed matter, less pollution, high efficiency, and saving the glitter powder at the same time.

Claim 1. A fully automatic glitter powder machine, comprising a powder dusting device, a powder recovery device, a conveying device and a frame, characterized in that the dusting device is arranged in the upper frame, A wind powder separator (25) and B The air powder separators (26) are arranged side by side on the upper frame (9), the upper frame (9) is arranged on the lower frame (4), the conveying device is arranged under the dusting device; the upper suction port (8) is arranged on the upper The suction pipe (22) is connected with the A-wind powder separator (25), and the left side of the upper suction pipe (22) is connected with the powder collecting hopper powder recovery pipe (20); the lower suction pipe (3) is arranged on the lower frame (4) , is connected with the B air powder separator (26) through the lower suction pipe (21), and one end of the lower suction pipe (21) is connected with the lower suction port equipped with a rotatable paper roller; Suction mouth device, the printed matter passes between the upper and lower suction mouths, the printed matter is sucked by the lower suction mouth, and the paper roller supports the printed matter without being scratched.

2. The fully automatic glitter powder machine according to claim 1, characterized in that in the dusting device, the dusting switch (14) is connected with the dusting port of the dusting hopper (13), and the dusting hopper (13) is connected with the dusting port of the dusting hopper (13). ) is fixed in the upper frame (9) by the spring plate (12).

3. By the fully automatic glitter powder machine according to claim 1, it is characterized in that in the described conveying device, the conveying belt is embedded in the semicircular arc groove of the transmission shaft with several beef tendon strips in two sections, and the conveying belt is fixed. Don't stray.

Patent Abstract The utility model relates to a fully automatic glitter powder machine, which consists of a dusting device, a powder recovery device, a conveying device and a frame. The air and powder separators are arranged side by side on the upper frame, the upper frame is arranged on the lower frame, the conveying device is arranged under the dusting device, the upper suction port is arranged on the upper suction port pipeline and is connected to the air powder separator A, and the left side of the upper suction port pipeline is installed. The surface is connected to the powder recovery pipe of the powder collecting hopper, so that the powder of the powder collecting hopper can be recovered into the dusting hopper; The lower suction port of the rotating paper roller is connected; so that the surface of the printed matter will not be scratched during the printing process of the glitter powder machine, and the excess powder on the top and the back of the printed matter can all be recycled into the powder hopper for reuse, which not only reduces environmental pollution, but also Improve productivity and print quality.

Related products: uv curing machine

Payment Terms︰ T/T L/C Western Union