Model No.︰TMP-70100

Brand Name︰Tamprinter

Country of Origin︰China

Unit Price︰-

Minimum Order︰1 set

Semi Work video:

https://youtu.be/0t3mcGgDmAI

https://youtu.be/EbHi7yVJyh0

https://youtu.be/nHgEUuxKpk8

https://youtu.be/_8ARcMfjFrc

Auto work video

With normal uv tunnel run to left

https://www.youtube.com/watch?v=REWl8zH-2Ik

With normal uv tunnel run to right

https://www.youtube.com/watch?v=_LHgMCYg-ks

https://www.youtube.com/watch?v=3bpxVNTvWF0

with led uv tunnel

https://youtu.be/6NGKTmtbf-w

with conveyor line run to left

https://www.youtube.com/watch?v=lsC3sVF322E

big type printer with Automatic glitter powder spill machine test video

https://youtu.be/_efN9mhuo7Q

operating instructions

http://doc.diytrade.com/docdvr/1963483/44230052/1443790819.pdf

PIC

http://doc.diytrade.com/docdvr/1963483/45122367/1463122264.pdf

|

|

| Model No. | TMP-6090 | TMP-70100 | TMP-90120 |

| Size of worktable (mm) | 720X1000 | 800X1100 | 1000X1300 |

| Max printing area (mm) | 600X900 | 700X1000 | 900X1200 |

| Max frame (mm) | 900X1200 | 1000X1300 | 1200X1500 |

| Min frame (mm) | 450X550 | 550X650 | 650X700 |

| Substrate thickness (mm) | 0-20 | 0-20 | 0-20 |

| Printing speed (pcs/h) | 500-1200 | 500-1000 | 400-900 |

| Working pressure(Mpa) | 0.3-0.5 | 0.3-0.5 | 0.3-0.5 |

| Air consumption 0.6Mpa | 13L/pcs | 13L/pcs | 13L/pcs |

| Height worktable to ground | 820mm | 820mm | 820mm |

| Dimensions(LXWXH)m | 1.55X1.15X1.46m | 1.8X1.37X1.5m | 1.95X1.55X1.55m |

| CBM | 3.9CBM | 4.1CBM | 4.7CBM |

| weight | 456kg | 480kg | 550kg |

| voltage /single phase | 220V 50Hz | 220V 50Hz | 220V 50Hz |

| power | 2.3kw | 3kw | 3.7kw |

Application:

Flat Screen Printer of this series is widely used in the packaging industry (cigarette packaging, wine packaging, gift packaging and other card paper printing) trademark, calendar, oil painting, computer keyboards, paintings, iron-on transfers, credit cards, stickers, printing; also suitable for the printing of the electronics industry.

Features:

(1). Printing machine is driven by motor drive, which is belt drive, sensitive, balanced speed, speed adjustable.

(2). Oblique arm lifting motor, frequency control, the machine runs smoothly.

(3). Blade and back blade pressure regulating device, and can be adjusted to the thickness and size of printing.

(4). Vacuum adsorption fixed printing pieces.

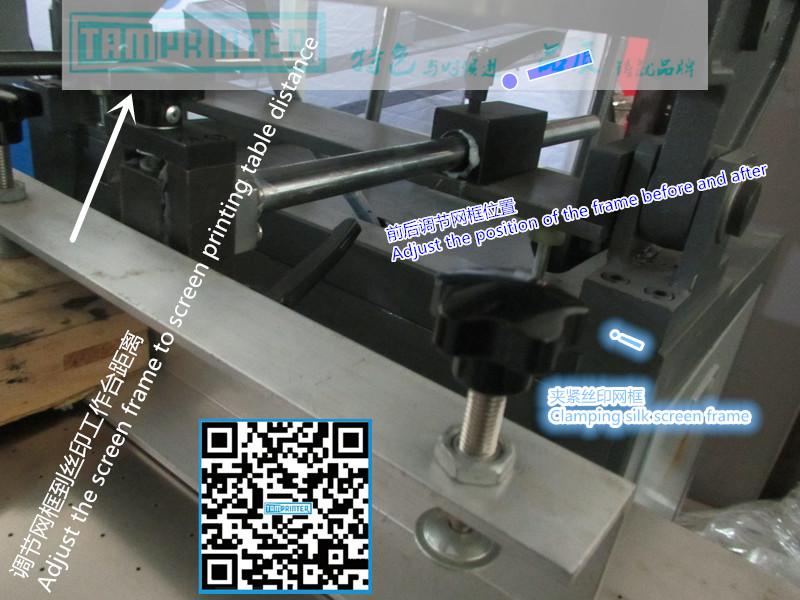

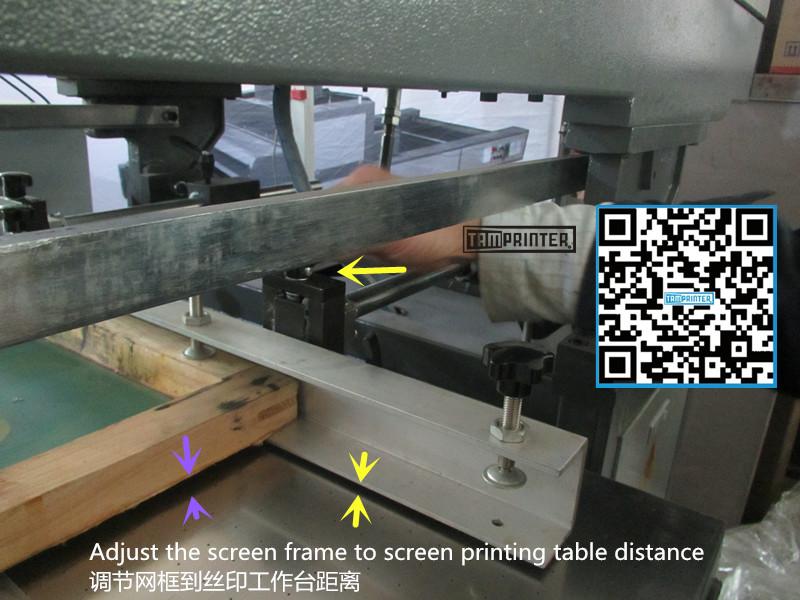

(5). The printing plate has up and down, left and right, before and after tuning device, which makes it works accurate and convenient on board.

(6). Equipped with a safety device so that the oblique arm is stopped in an upper position having a reliable security.

(7). Electronic control unit centralized control by the microcomputer controller, the whole operation more simple, flexible, and easy maintenance.

Screen printing is a printing technique whereby a mesh is used to transfer ink onto a substrate, except in areas made impermeable to the ink by a blocking stencil. A blade or squeegee is moved across the screen to fill the open mesh apertures with ink, and a reverse stroke then causes the screen to touch the substrate momentarily along a line of contact. This causes the ink to wet the substrate and be pulled out of the mesh apertures as the screen springs back after the blade has passed.

Hot tags: manual screen printing machine

Related auxiliary equipment: 25kw UV tunnel dryer for Glitter powder coating and uv glue coating

Payment Terms︰ T/T L/C Western Union