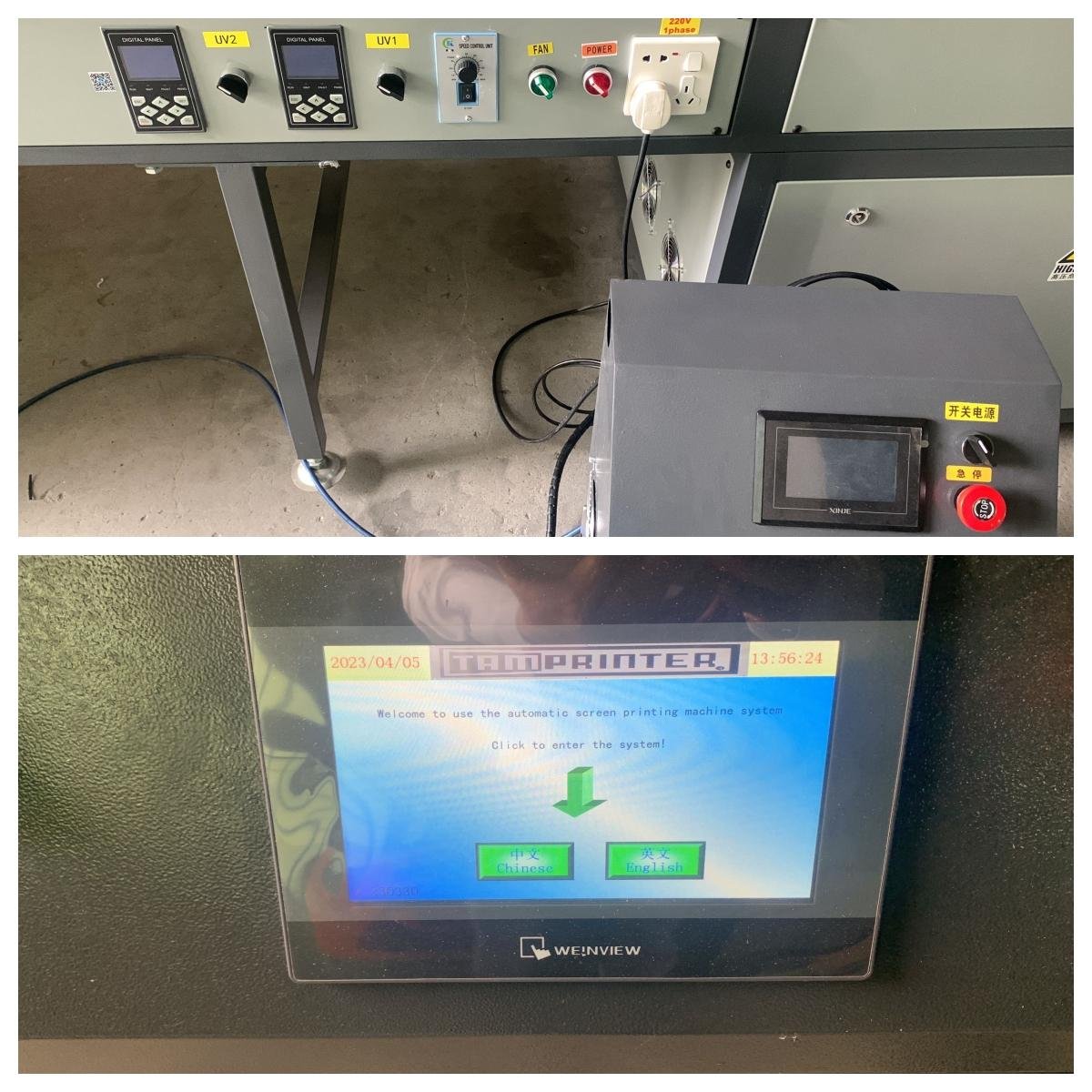

Model No.︰TM-Z2-50140A

Brand Name︰TAM

Country of Origin︰China

Unit Price︰US $ 24075 / set

Minimum Order︰1 set

Applications :

Mainly for signs factory, paper box packaging silk screen processing plants, Electronics, toys, gifts, clothing, stationery, cosmetics, washing products, chemicals, food, health product, pharmaceutical and packaging etc.

Advantages:

1, servo motor drive, printing runs smoothly, High precision printing for big size printing;

2, UV light source , Drying uv ink on sheet is very fast than heat dry ink;

3, Energy saving and environmental protection, Suitable for clean room(dust-free workshop).

parameters:

|

PLC double servo motor Super precis screen printer 8443198000 |

Model No. TM-50140A double Servo + PLC X/Z servo Print area 500X1400mm Table size 700X1600mm Max frame 800X1700mm Printing thickness 0~ 20mm Overlay accuracy 0.05mm Workbench height from ground 840mm Platform precision About +/-0.06mm Printing pressure 4.0-8.0 kgf/cm2 Air pressure(mpa) 0.5~0.6(Mpa) Air consumption 35L/min Printing speed 650pcs/h Power:220VAC, single phase /2.5KW Dimensions (LXWXH)mm 2250mmX1250mmX1780mm Weight 500kg 5CBM Free fitting AL squeegee holder 500mm--1pcs, AL flood bar 520mm---1pcs; AL squeegee holder 300mm--1pcs, AL flood bar 320mm---1pcs. Tool box |

|

TM-UV750L UV Machine 8543709990

With

Auto Robot Arm 1750

|

Electric power Step-less dimming energy-saving style Conveyor belt width(mm) 730 Effective range (mm) 750 Product max height (mm) 40 Conveyor speed (m) 2~20 Belt to ground 840mm Power:380VAC, 3 phase UV lamp(KW/2pcs)5.6 Conveyor power(W)90 Total power(KW)12.1 Dimension(L*W*H)4050*1200*1350//4210*1260*1610 8.6CBM Weight(kg) 300 |

|

1,Working air pressure(Mpa): 0.3-0.5 2,Gas consumption(0.6Mpa)(L/pcs): 0.5 3,power(kw): 0.75 4,Power:220VAC, single phase 5,Take the feed rate (pcs/h): 1000 6,Dimension(L*W*H)mm : L1750* W700* H 200 7,weight(kg): 40 8,The clip grabs the product and drags it Run from left to right 9,The control panel is button + microcontroller + display |

|

|

Transformer 8504339000 |

208V3phase to 380V3phase (for UV machine)+ 220V single phase(for robot arm ,sharpening machine,screen printer) |

|

TH-800-p Squeegee Sharpening Machine 8477800000 |

Grinding stroke 800MM Grinding thickness 5MM-20MM Grinding angle 90 Power:220VAC, 1 phase Total power0.37KW Machine size L165 * 500 * 86 CM=1.25CBM Machine weight 96KG+40kg plywood |

|

TM-50DG Thousand layer Cart7326909000 |

galvanized Drying Rack Trolley 50 layer layer to layer 25mm Screen Size 65*100cm, 12 * 12CM grid Wire diameter 4.6 *2. 3mm 4 inch wheels (1 set plywood size L 1.25*W 0.9*H 1.65m=1.86CBM 65kg 6 set plywood size L 2.1*W 1.38*H 1.6m=4.64CBM 75sets = 20gp) |

|

scraper assembly 8443919090 |

250mm AL squeegee holder |

|

270mm AL flood bar |

|

|

scraper assembly 8443919090 |

350mm AL squeegee holder |

|

370mm AL flood bar |

|

|

Ink Squeegee 3926909090 |

50mmx9mm*4M single layere 55 shore ,Sectional shape G1 brown |

|

50mmx9mm*4M single layer 65 shore, Sectional shape G1 brown |

Packaging industry printer for

Box and Packing

Coloring Book

Coffee Table Photo Book Printing

Book Printing

Brochure Printing

Catalogue Printing

Cookbook Printing

Children Book Printing

Calendar Printing

Dictionary Printing

Magazine Printing

Notebook Printing

Publications Printing

Special Finishing Book Print

Textbook Printing

Year Book Printing

Yellow page Printing

FAQ

Q1:

How difficult would it be to modify our printer with a squeegee on both sides, and change the program to print in both directions ?

R-L, lift... 1 print... L-R, lift... 1 print

1st print - Squeegee pressure R-L, then raise. New substrate... 2nd print - Squeegee pressure L-R, then raise. (each direction is 1 print with new sheet).

The reason is, we are using a stencil with holes. Pushing the ink L-R with the aluminum blade causes the ink to leak through the holes. It would be better if we printed, once in one direction, then once in the other direction.

what is required ? A squeegee on both sides ? If you can show me the parts, I will understand. I am mechanical engineer and design machines as well.

I also work with PLCs and can make modifications

A1:

Solution 1

cancel flood bar ,change to 2 squeegee

Solution 2

Directly cancel the oil return scraper , only use 1 squeegee scraper to move back and forth

The risk lies in the action interference. Pay special attention to dragging the uv machine away first to ensure a safe distance from the screen printing machine to prevent fights and ensure that the robotic arm does not touch the screen printing machine during the debugging process.

Ensure that the movements are coordinated and meet the requirements, and then the two parts are sent to the correct position

The robot PLC program should not need to be changed

Q2:

Can it be done with just a program change ? This would be ideal. I guess one squeegee would print in both directions.

A2:

The U disk file can only change the touch screen display, and the PLC program file becomes the desired action, which needs to be continuously debugged. The machine is not in China, it is difficult to achieve. We suggest that you will work on the current state, single squeegee printing, the left and right tilt angles are inconsistent, and you need to adjust the descending height of the head during the return printing process

Looking forward to your video feedback on normal production status,thank u

Q3:

How much time will the reprogramming take ? Can we upload the new program ? We have very little time to make this work.

A3:

Express back and forth plus programming time, you budget 40 days

Disassemble the touch screen and PLC and send them to us for modification.

Pay special attention to the risks, it is easy to disassemble and difficult to put back, and it is very dangerous to connect a wrong wire, remember to record the whole process for backup.

Remember to videotape the whole process of disassembly and assembly for future reference.

Q4:

I need it working in a week. Do we have access to the program ? I have a good programmer if it is a change in the logic sequence.

A4:

First ask him if your programmer can understand the existing program, if he can understand the original command code, keep a backup, and then try to change the code

If your programmers can't understand the factory code, try not to change it.

Because DHL express usually 7~15days

Q5:

Thankyou... we are working with the program, but it will be difficult to do ourselves. We have no trouble loading a new program on the PLC. Can you generate an updated program for the 2 direction printing ? We can gladly pay for the change.

This work is urgent and we need the change asap - please let me know if there is any option to expedite the work.

A5:

This program change cannot be implemented remotely, it must be debugged on site, and it is too expensive for engineers to go to Canada

Q6:

Ok, I thought you wanted the PLC shipped back for programming (which seems like just loading the program), I don't know how that helps debug.

I must have misunderstood.

A6:

Thank you for providing us with a design idea,

The next time I encounter long strip printing, I will advise customers to print bidirectionally to improve efficiency.

You have contributed to the industrial development of mankind, and you can also apply for a patent.

Q7:

Getting close. We have the full size stencil now. The squeegee travel is not parallel to the table. 10mm higher at one end. Is there adjustment for this ?

A7:

First, you can adjust the control handle of the screen frame to reach a distance of 5~8mm from the platform.

Adjustable workbench

Disassemble the cover plate, there are screw adjustments inside

If it is adjusted to the limit, put something in to level the workbench

There should not be so much difference. We adjusted the workbench level when assembling.

Q8:

Strange... We have a new PLC program ready to download to the PLC, but are getting an "unlock error"... The 201129 pass doesn't seem to work. Any ideas? Is there a trick to connecting to the PLC ?

A8:

PLC program not free, you bought? and get key?

The new PLC has a password, you have to ask the PLC program supplier

Q9:

A problem I am encountering now is that the parameter setting on the HMI side is not synchronized with the parameter setting on the PLC program. It means that when I adjust the parameter setting on the touch screen, that parameter will not be adjusted. For example, "pan manual speed". Do you have any ideas, or do you know what causes the communication between HMI and PLC to be out of sync?

A9:

If it can’t be adjusted, it means that the address of the touch screen does not correspond to the PLC or the data format is wrong. If you don’t know how to program, it’s best not to start the program, otherwise it will become more and more chaotic.

Relevant information can be found on Xinjie official website

It is written on the screen, the PLC has not been changed, it must be a problem with the format of the data address

TAMPRINTER printers in the paper packaging industry operate in the following categories:

Bank card screen printing machine

Tobacco and Alcohol Gift Box UV Ink Automatic Screen Printing Machine

Picture album greeting card golden vermicelli printing machine production line

TAMPRINTER, a printing machinery for the sign and nameplate industry, operates the following categories:

Home appliance panel precision electric screen printing machine

Logo sign flip type screen printing machine

IMD precise screen printing machine

Blister injection T-slot screen printing machine

Instrument panel vacuum suction screen printing machine

Film button ultra-precision screen printing machine with automatic stacker

The operating categories of TAMPRINTER printing equipment in the electronic optics industry are as follows:

Light guide plate dust-free workshop screen printing machine

Mobile phone glass cover to prevent dripping oil screen printing machine

PCB green oil solder paste screen printing machine

FPC precision register screen printing machine

High-volume and rapid production of printers for electronic originals

TAMPRINTER's business categories in the apparel leather industry are as follows:

Mark mark automatic screen printing machine

Garment fabric roll-to-roll drying tunnel furnace

Luggage hot stamping machine

High-speed screen printing machine for shoe material

The business categories of TAMPRINTER in the transfer heat transfer industry are as follows:

Ceramic floral paper vertical screen printing machine with LED UV curing system

Wine label water transfer to prevent deformation low temperature ultraviolet ray dryer

Cycling decal and color screen printing machine with automatic stacker

Mark heat transfer infrared industrial tunnel furnace

Equipment transfer screen printing dryer

TAMPRINTER's business categories in the home improvement board industry are as follows:

Decorative glass large size flat screen printing machine

Integrated ceiling screen printing production line

Mupei building material varnish curing machine

TAMPRINTER's business categories in the sports equipment industry are as follows:

Bicycle decal continuous screen printing machine with drying production line

Cue Fishing Tackle Curved Screen Printing Machine

Fitness equipment pad printing hardware infrared oven

Outdoor supplies screen printing auxiliary equipment

Payment Terms︰ TT/LC/Western Union